RobBox

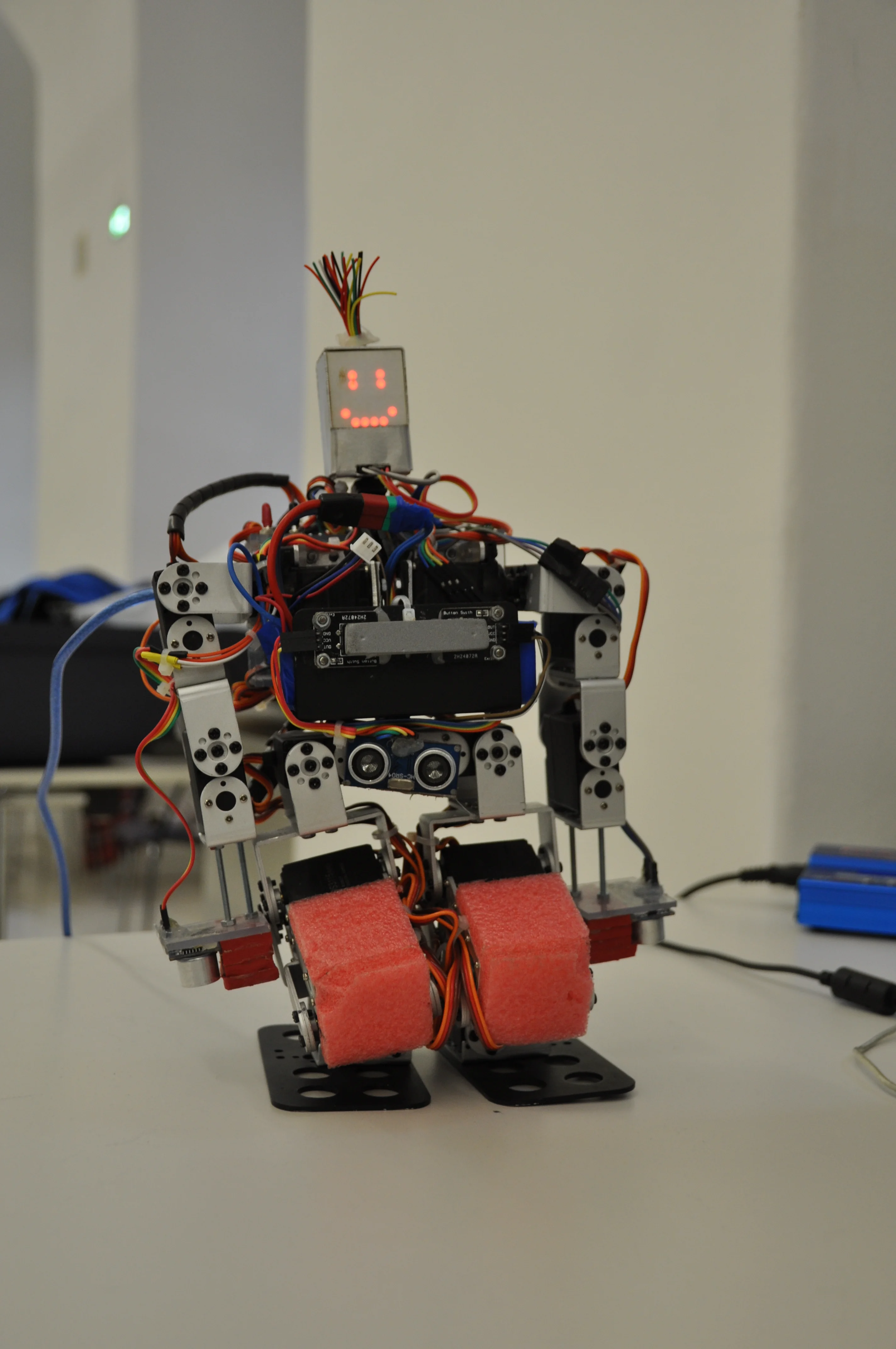

The First Steps: A Simple Prototype

The journey started with building a prototype that could move a single servo motor. From there it took me three months to get the first working upper body prototype and another four months to a bipedal version.

First Upper Body Prototype

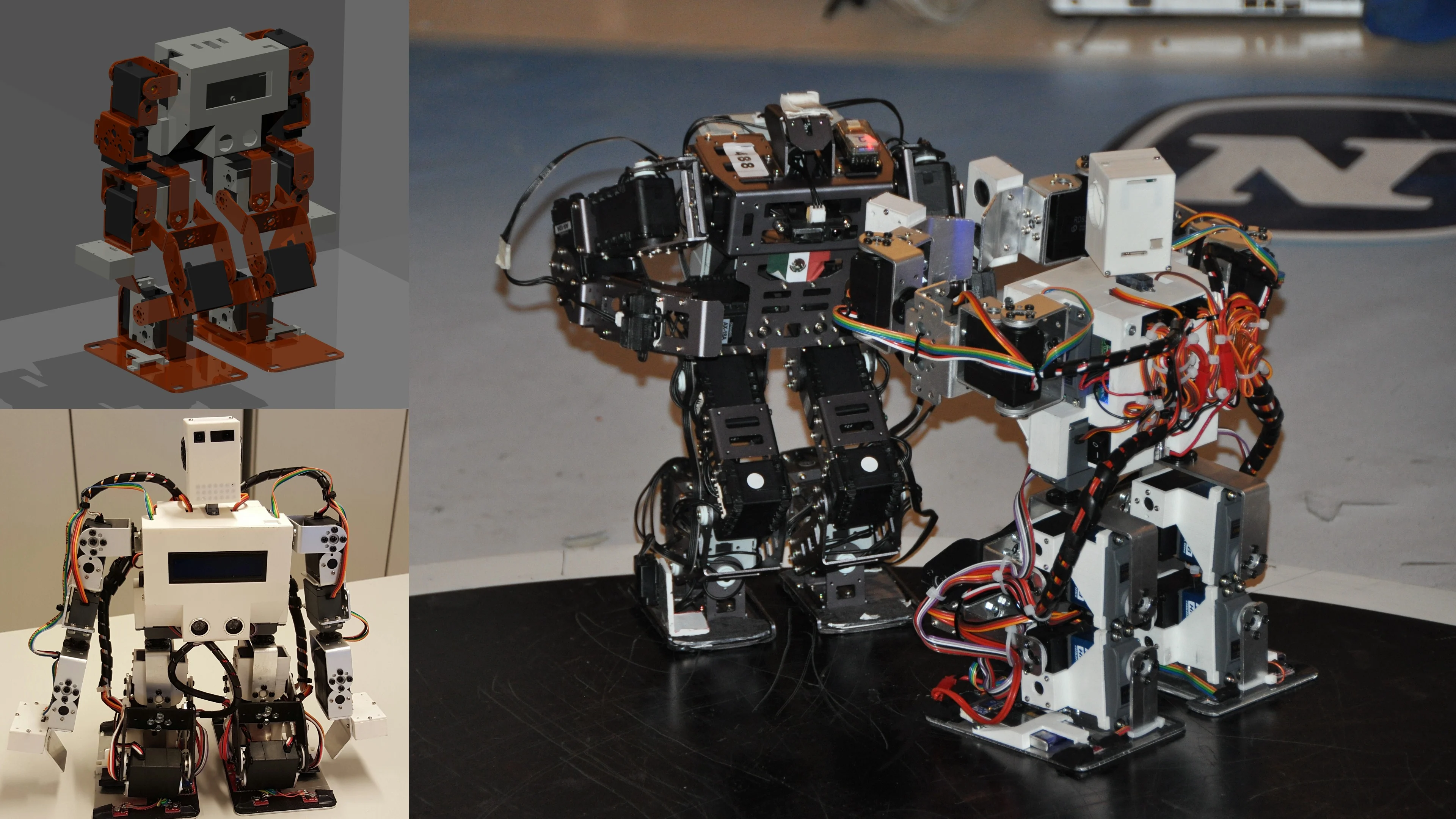

Simplifying the Design

By removing unnecessary complexity in the shoulder joints, a second bipedal version was built. This iteration was still made entirely of wood but was more functional and efficient.

Second Bipedal Version in Action

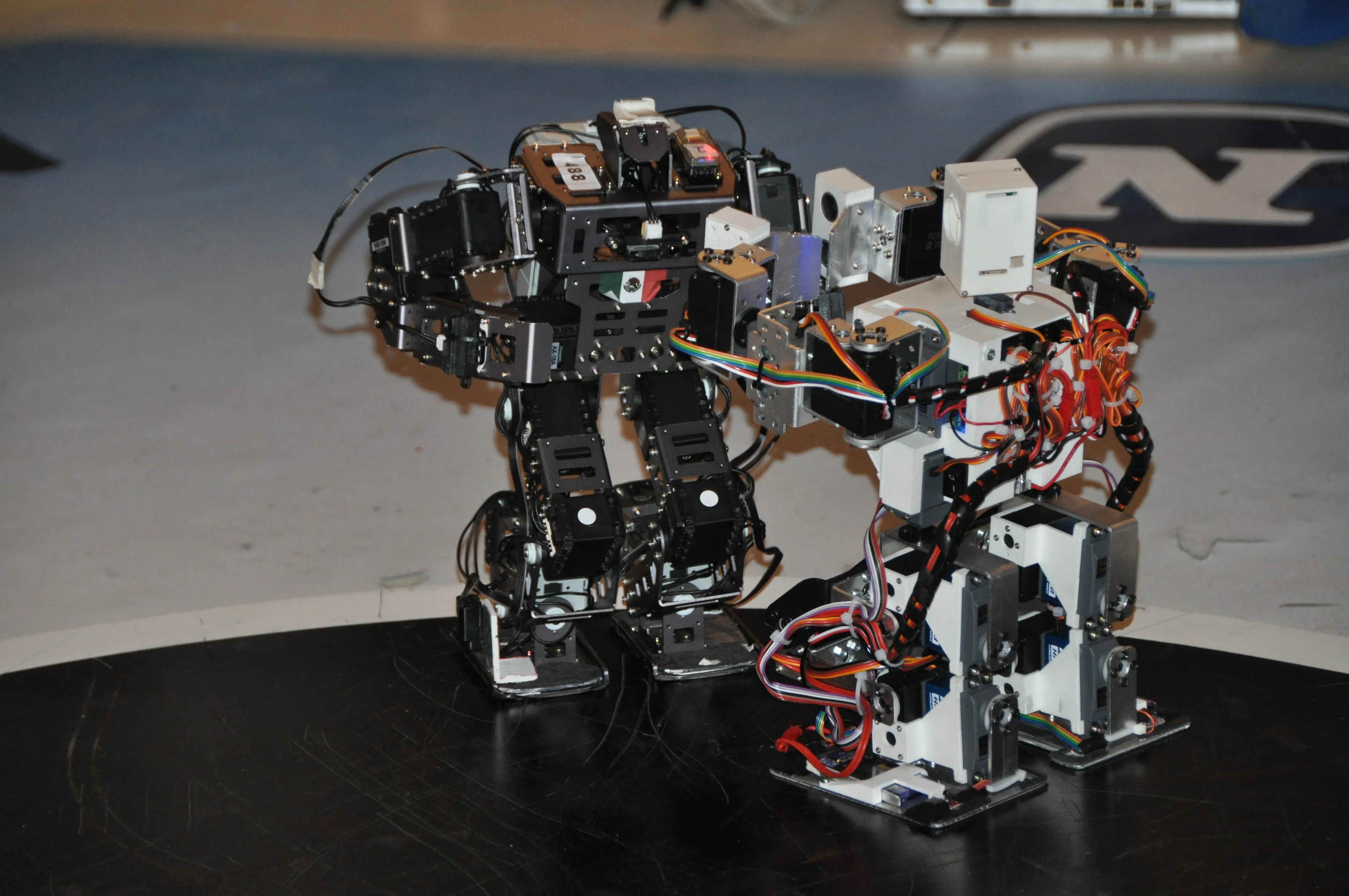

Transitioning to Metal and Competitions

The next iteration involved the use of metal parts, enhancing robustness and precision. This version competed in its first robotics competition.

A Version Manufactured from Scratch

Three years into the project, RobBox was fully manufactured from scratch and won a competition in China, highlighting its refined design and capabilities.

Competition-Winning Design in Action

From Builder to Judge

Following years of development and competition success, I transitioned to judging robotics competitions, sharing my expertise and inspiring others to innovate.